The GD350-UL series includes. High-performance vector invertersfor any type of electric motor and industrial application.

The result of more than 5 years of R&D work, the GD350 series is designed to meet any type of application requirement, even the most complex.

Innovative vector management algorithm with direct current control "I/F mode" (with or without sensor)the ability to control any type of motor (asynchronous or synchronous)and advanced torque control functions and the integrated positioner; allow the devices in this series to be used successfully in highly complex applications.

Infinite expansion possibilities

Built-in expansion slots allow you to increase the functionality of GD350 high performance vector inverters with communication extension boards (Ethernet, CANopen, Profibus, Profinet, EtherCAT, DeviceNet), feedback interfaces (incremental encoder, absolute encoder, resolver), I/O modules, integrated PLC board.

The Bluetooth module allows the inverter to be accessed and programmed by smartphone.

The integrated USB port allows simple and immediate connection to a PC for drive programming and monitoring.

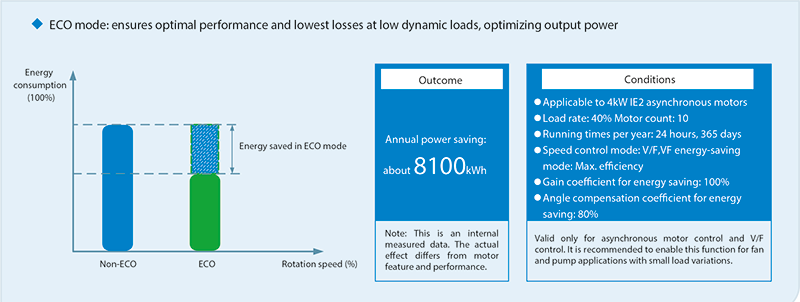

Energy saving with ECO-MODE

The innovative ECO-MODE mode of operation available in the GD350 series can contribute, along with other interventions, to achieving the energy-saving goals set forth in the Transition 5.0 Plan, offering a noticeable advantage, in terms of consumption, over control modes with traditional Inverters.

ECO-MODE optimizes the efficiency of the motor-inverter system in a fully automatic way, acting directly and independently on the voltage/frequency curve and establishing the optimal V/F ratio for maximum motor efficiency under any load and speed conditions.

ECO-MODE allows the greatest energy savings in machines that do not require frequent acceleration and deceleration, allowing the system to self-regulate and, if necessary, autonomously shut down in the face of sudden changes in frequency and/or load.

Activation of the ECO-MODE function is done with a single parameter, no complex programming, no detailed knowledge of system dynamics. If the application allows it, ECO-MODE will allow the system to reduce its consumption totally autonomously, without impacting machine operation.

Main features

- Output frequency 0.0-600Hz

- 400V and 600V versions and IP20 or IP54 (400V only) available

- Vector management algorithm with direct I/F current control sensorless or with feedback for asynchronous and synchronous permanent magnet motors

- Overload max 200% rated current

- Integrated EMC filter C3 on all models

- Integrated braking unit for powers up to and including 37kW(30kW for UL versions)

- STO function (Safety Torque Off) SIL 2 safety level

- ECO-MODE function for energy saving

- 4 programmable digital inputs

- 2 Digital inputs/pulse train 50KHz

- 2 digital outputs, 2 relays and 1 analogue output

- RS-485 Modbus RTU/ASCII interface as standard

- Standard keyboard on all models usable as an external remote keyboard

- Speed, torque and position control

- Dual set of independent motor parameters

- Possibility of heatsink through mounting

Dedicated firmware for specific applications

Optionally, GD350 series inverters can be 'customised' with dedicated firmware for specific applications. See some examples:

GD350-16 Dedicated firmware for pumping systems

GD350-16 is a FW dedicated to pumping systems for different areas of use

-

- Control of pumps with asynchronous or synchronous permanent magnet motors

- Alternation control of up to 4 pumps

- View setpoint e feedback in the actual unit of measurement

- Dual PID controller and differential feedback from dual transducers

- Function "pump cleaning”

- Function sleep advanced

- G Mode (Heavy Duty) and P (Normal duty)

- Emergency operation mode for fire-fighting systems

GD350-19 Dedicated firmware for lifting equipment

GD350-19 is a FW dedicated to all types of lifting equipment: overhead cranes, construction cranes, harbour cranes, conveyor/elevator belts, gantry cranes etc.. The firmware has been developed with the technical contribution of some of the most important global companies operating in the lifting solutions sector.

-

- Optimised control of motors with conical rotors, even when revamping old systems

- Intelligent brake logic

- Automatic speed/load optimisation and electronic load cell

- Control of permanent magnet synchronous motors

- Load pendulum control

- Master/slave synchronisation control

- Rotation function management for construction cranes

- Rope tension control

For more information about INVT products visit: www.invt.com.

Reviews

There are no reviews yet.