Industry 4.0

What is Industry 4.0?

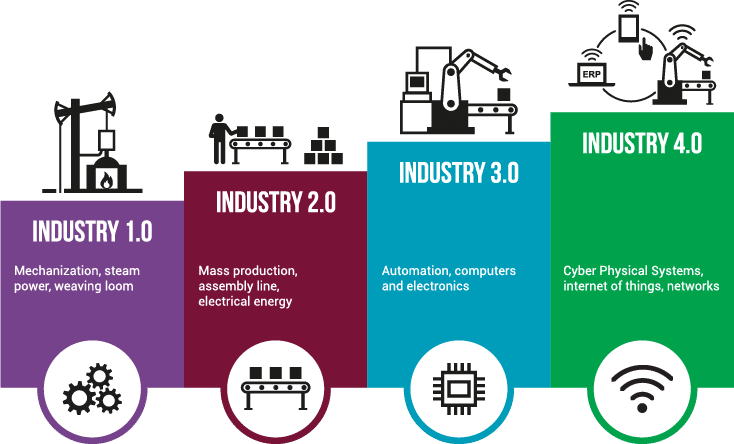

With the term Industry 4.0 (or Industry 4.0) indicates a trend in industrial automation that integrates new production technologies to improve working conditions and increase productivity and production quality of plants.

It takes its name from the German government's business plan, presented in 2011 and implemented at the end of 2013, which included investments in infrastructure, schools, energy systems, research institutions and companies to modernize the production system.

The Fourth Industrial Revolution

The productive results achieved by Germany have led other countries to pursue this policy. Several studies have led to define the impact that these new policies will have on the social and economic context, calling this historical step "Fourth Industrial Revolution".

From research The Future of the Jobs presented to World Economic Forum It has emerged that, in the coming years, technological and demographic factors will profoundly influence the evolution of work. Some of them, such as cloud technology and work flexibility, are already influencing the dynamics and will continue to do so even more in the coming years.

Enabling technologies

From a study by Boston Consulting it emerges that the fourth industrial revolution is based on the adoption of certain technologies defined as enabling technologies. Some already known, concepts already present but that have never crossed the dividing wall between applied research and real production systems and that today, thanks to the interconnection and collaboration between systems, the global market landscape is leading to mass customization, becoming of interest for the entire manufacturing sector.

The 9 enabling technologies defined by Boston Consulting are:

- Advanced manufacturing solution;

- Additive manufacturing;

- Augmented reality;

- Simulation;

- Horizontal e vertical integration;

- Industrial internet;

- Cloud;

- Cyber security;

- Big Data Analytics.

The advantages

L’Industry 4.0 will lead to a radical change in production methods towards fully automated and interconnected processes. The network connection is central to the company; all machines and production departments will dialogue with each other within the factory, but not only; through the Internet they will also be able to dialogue with suppliers and customers.

Production will be optimized through process automation, reducing errors and waste by anticipating the right instructions to operators.

This new way of working based on the exchange of information between participants will lead to:

- Higher productivity, through reduced plant set-up times with reduced errors and consequent machine downtime.

- Greater flexibility, allowing the production of small batches at the typical costs of economies of scale.

- Increased speed, process efficiency leads to a reduction in the time needed to move from prototyping to series production.

- Improved quality, continuous monitoring of the production phases and exchange of information allows a reduction in the number of defects.

The Transition Plan 4.0

In order to start the transformation towards industry 4.0, the governments of the various European countries have launched programs to help companies that invest in modernizing their plants, adopting automation and connectivity techniques.

Italy has also moved in this direction, since we are the second manufacturing country in Europe and the seventh in the world.

The Transition 4.0 Plan is the country's new industrial policy, more inclusive and attentive to sustainability. In particular, the Plan provides for greater attention to innovation, green investments, and design and aesthetic design activities.

The main actions

Tax credit for investment in capital goods

To support and encourage companies that invest in new capital goods, both tangible and intangible, functional to the technological and digital transformation of production processes destined to production structures located in the territory of the State.

Tax credit for investments in Research, Development, Innovation and Design

Stimulate private spending in Research, Development and Technological Innovation to support the competitiveness of companies and to foster the processes of digital transition and within the circular economy and environmental sustainability.

Tax credit for investments in Training 4.0

Stimulating investment by companies in staff training on subjects relevant to the technological and digital transformation of companies.

See the official information on the MISE website.

Our proposals in the field of Industry 4.0

The legislation provides for a series of minimum requirements for a machine (or a plant) to fall under the Transition Plan 4.0 and, therefore, to benefit from the incentives. Elsist offers a wide range of products in line with the requirements:

- Programmable controllers, designed and built by us, all with network interface and typical IoT protocols.

- Hw-Group products for the IT world, of which we are exclusive representatives for Italy, with their cloud solutions.

- Industrial mobile phone routers, to connect to the Internet from anywhere with wireless connectivity in UMTS (3G) or high speed LTE (4G).

- Weintekoperator terminals, which allow a simple and intuitive operator interface with touch screen panels. Through EasyAccess the operator panel allowsremote access to the plant via Internet.